Revolutionizing the Air Cargo Net:

Dyneema Nets and the Future of Lightweight Efficiency

KLM CEO Camiel Eurlings: “At Air France-KLM, we are fully committed

to reducing our carbon footprint, and our efforts are being recognized.

For the eighth year running, Air France KLM has come out at the top

of the Dow Jones Sustainability Index in the airline sector.”

In the dynamic world of air cargo, where weight is a critical factor, the choice of materials plays a pivotal role in aviation efficiency. Unlike land and sea cargo, air cargo containers and pallets demand a delicate balance between strength and weight due to the reliance on jet fuel for lift. This distinction becomes evident when comparing the robust and weighty containers of other modes of transportation with the tailored, lightweight aluminum alloys used in air cargo.

Challenges in Air Cargo

The unique challenges of air cargo lie in two essential factors: the strength-to-weight ratio of Unit Load Devices (ULDs) and the impact of wear-and-tear on the aircraft. As planes are designed for optimal strength-to-weight ratios to maximize fuel efficiency, the materials used in ULDs must align with these stringent requirements. Additionally, the wear-and-tear on the aircraft, especially during loading and unloading, poses a continuous challenge.

Traditional Solutions with Polyester Nets

The traditional air cargo net has mostly been constructed using polyester fibers to address the need for strength. While knotted nets enhance their strength for heavy loads, they present challenges such as increased tare weight due to the additional webbing material and potential friction and wear caused by the rough and abrasive knots.

Innovation with Dyneema Pallet Nets

A groundbreaking shift occurred in July 2013 when the Air France-KLM Group embraced the knotless Dyneema air pallet net. Dyneema is crafted from ultra-high-molecular-weight-polyethylene (UHMWPE), which is the world's strongest and lightest fiber. Recognized for its exceptional tensile strength, minimal elongation, and low density, Dyneema exhibits excellent resistance to fraying and abrasion.

Quantifiable Benefits

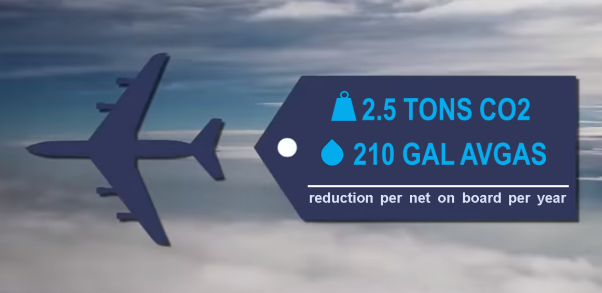

Adopting Dyneema nets allowed the Air France-KLM Group to eliminate knotted nets, contributing to significant annual savings. Each knotless Dyneema air cargo net, weighing about half that of traditional polyester nets (9 kg. compared to 18 kg.), resulting in a remarkable annual saving of more than 210 gallons of jet fuel per net. This innovation also led to a noteworthy reduction of over 2.5 tons in carbon dioxide emissions per net per year.

The unique challenges of air cargo lie in two essential factors: the strength-to-weight ratio of Unit Load Devices (ULDs) and the impact of wear-and-tear on the aircraft. As planes are designed for optimal strength-to-weight ratios to maximize fuel efficiency, the materials used in ULDs must align with these stringent requirements. Additionally, the wear-and-tear on the aircraft, especially during loading and unloading, poses a continuous challenge.

How Can We Help You

Welcome to CargoSecures, your trusted partner in air cargo safety. How can we tailor your order today? Specify your requirements below, from customizable aesthetics to ultra-durable nets and webbing crafted with the world’s strongest yet lightest fiber. Let's craft a solution that ensures your cargo reaches its destination securely with the least added weight.