Fatal Oversight: How Cargo Strapping Failures Led to the Tragic Downfall of National Airlines Flight 102

In a devastating turn of events, the ill-fated National Airlines Flight 102 met its demise due to critical errors in cargo strapping procedures. What began as a routine cargo flight turned into a catastrophic event, claiming the lives of all seven American crew members on board.

Departing from Chateauroux, France, the flight was destined for Camp Bastion (now Camp Shorabak), Afghanistan, where the crew loaded 207,000 lbs of cargo consisting of five heavy Mine-Resistant Ambush Protected (MRAP) vehicles securely

fastened by chains to specialized pallets. After a stopover at nearby Bagram Airfield for refueling, the Boeing 747-400 continued its journey to Al Maktoum Airport in Dubai. Despite the aircraft's weight remaining significantly below the safe limit and the cargo being correctly positioned for balance, tragedy struck shortly after departure from Bagram Airfield on April 29, 2013.

During a routine cargo hold inspection at the layover, First Officer Jamie Lee Brokaw uncovered a critical flaw: a broken strap, signaling a potential hazard that went unaddressed. His observations, recorded on the Cockpit Voice Recorder, underscored the alarming movement of one of the MRAPs during the flight from Camp Bastion, which should have been securely anchored.

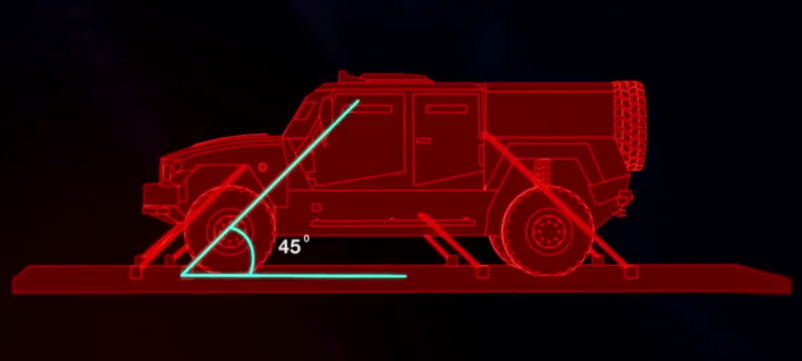

Despite Brokaw's warning, Loadmaster Michael Sheets failed to adequately rectify the issue. Lacking proper certification and guided by inadequate procedures outlined in the airline's cargo operating manual, Sheets repeated ineffective strapping methods. Crucially, the manual failed to incorporate crucial guidelines from Boeing regarding anchoring angles, impacting the straps' load capacity. This oversight proved fatal, as the inadequate strapping failed to prevent the 12-ton Oshkosh M-ATV from shifting during takeoff, breaching the aircraft's structure and rendering it uncontrollable.

To get the maximum load capacity of a 3,500-lb strap, it has to be pulled directly

Increasing the angle lessens the load capacity

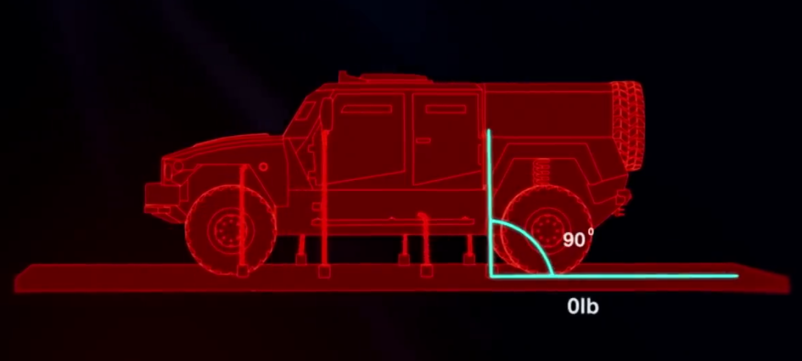

At a 90-degree angle, load capacity is worth zero

The MRAP vehicle broke its straps, slid back during take-off, and broke the jack screw

of the plane’s horizontal stabilizer, rendering it uncontrollable

Subsequent investigations by the National Transportation Safety Board (NTSB) identified National Airlines' deficient cargo handling procedures as the primary cause of the tragedy. Among the key recommendations was the implementation of mandatory certification for all cargo handling personnel, a measure that has since become an industry standard.

The loss of National Airlines Flight 102 serves as a poignant reminder of the critical importance of meticulous cargo handling procedures and comprehensive safety protocols within the aviation industry. May the memory of those lost in this tragic accident inspire lasting improvements to ensure the safety of future flights.

Watch the full reenactment below:

How Can We Help You

Welcome to CargoSecures, your trusted partner in air cargo safety. How can we tailor your order today? Specify your requirements below, from customizable aesthetics to ultra-durable nets and webbing crafted with the world’s strongest yet lightest fiber. Let's craft a solution that ensures your cargo reaches its destination securely with the least added weight.